Rotary Drum Filter - Sea Water Aquaculture

Application: aquaculture, sewage treatment plants, chemical plants, food plants, etc.

Basic structure and working principle

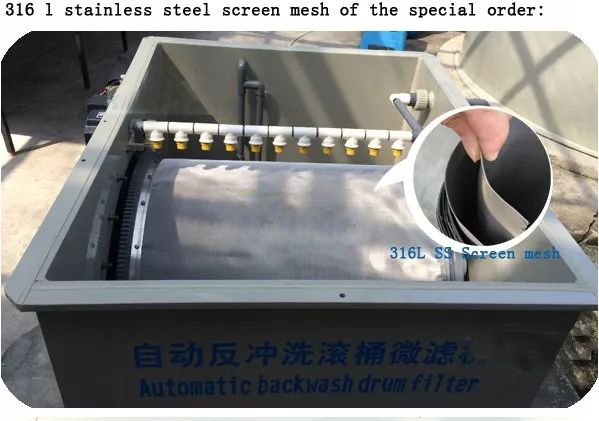

- It uses a rotating stainless steel drum screen to achieve filtration. There is a dense 316L stainless steel screen on the outside of the drum. The drum screen can be driven by a motor through gears.

- On the outside of the filter, there is a pressurized water pump composed of a plastic pump casing. The pressurized water pump is connected to a row of plastic nozzles.

- Inside the box, there are two water level controllers, which can transmit signals to the control electric box according to the water level change.

- There is a large-diameter water inlet, a small-diameter drain, and a sewage pipe on the box body. The drainage adopts the rear-mounted water pump.

Design features:

- Adopts SS316L drum screen: can withstand the liquid with PH over 11 for a long time without rust. And a special weaving method is used to increase the strength of the screen.

- The driving mode of the drum is changed from the central shaft drive to the external gear drive. The probability of failure is greatly reduced and the screen can be washed more cleanly.

- The drum screen adopts the form of outer flange to make it is easier to repair, replace or clean.

- The water level controller is a non-contact solenoid type to prevent seawater corrosion or other matters from entering.

- The outlet pipe is connected to the water pump which can make the rotary drum filter has a larger effective filtering area and reduce the frequency of backwashing.

- There are many options for backwash control, such as water level control, timing control, time interval control, and manual control.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160