How to Fix the Deformed Ring of Volute Dewatering Machine?

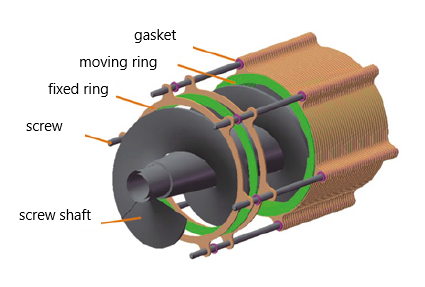

The critical elements of Volute Dewatering Machine is fixed and moving ring, sometimes the rings are easily deformed due to poor quality or large feed flow, lots of solids in the sludge. How to avoid these problems?

Causes

1. Equipment quality problem. The filtration cavity formed by the stacked fixed and moving ring pieces of the Volute Dewatering Machine will produce relative movement between the fixed and moving ring pieces when the Volute Dewatering Machine is running. If the flatness between the ring pieces is not enough or the thickness of the ring pieces is not enough, then, the Volute Dewatering Machine in the process of use, the inner ring pieces or wear serious, resulting in soaking sludge and sludge leakage. After using for a long time, the ring pieces will be extruded and deformed.

2. Feed flow is too large. Different models of Volute Dewatering Machine correspond to different models of treatment capacity, the feed flow should be adjusted according to the actual processing situation of the Volute Dewatering Machine, pharmaceutical debugging, etc. If the feed flow is too large to exceed the range that the main body of the Volute Dewatering Machine can withstand, the ring piece will be overloaded and deformation will also occur.

3. Related to the nature of sludge. If the sludge contains sand, oil, rubber, a lot of solid waste, easy to dry sludge dead mud, not only easy to block, but also will lead to internal pressure imbalance, resulting in the Volute Dewatering Machine ring piece wear and deformation.

Solutions

1. First of all, we have to prevent the problem before it happens, before buying the equipment, do not only care about the price of the equipment, must learn more about the quality of the product and after-sales service, etc., to ensure that the quality of the equipment itself is not a problem.

2. About the feed flow, can be adjusted according to the valve, in the installation, it is best to add an overflow pipe, when the flocculation tank of the Volute Dewatering Machine is too full of feed, it will flow back through the overflow pipe, so as to reduce the operating load of the ring piece of the stacked spiral machine.

3. Ensure the concentration of the feed material of the Volute Dewatering Machine (related to the adjustment of pharmaceuticals), if there are large slag pieces, metal impurities, etc. in the material, it is necessary to add a filtering device at the inlet end.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160