How is the Sieve Bend Screen Used to Separate Fish Skin from Water?

In the aquatic product processing industry, the separation and treatment of fish skin is a key link in improving resource utilization. Traditional separation methods often face problems such as low efficiency, high energy consumption, and easy clogging. Sieve Bend Screen Filter has become an innovative equipment for fish processing plants to achieve efficient separation of fish skin and water with its unpowered, high-precision, and strong adaptability.

1. Working principle of hydraulic screen: gravity drive, precise filtration

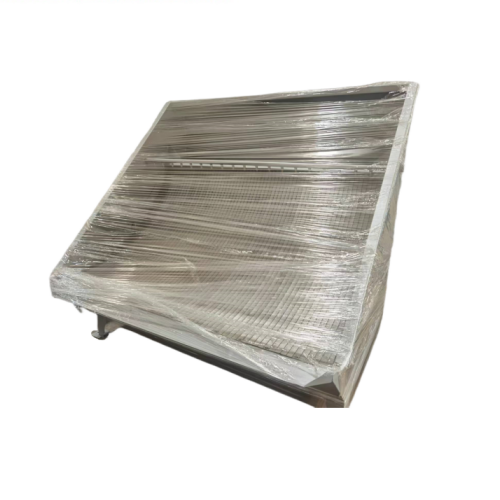

The sieve bend screen adopts a wedge-shaped stainless steel screen design to achieve solid-liquid separation through the natural gravity of the water flow. The fish skin wastewater to be treated is evenly distributed to the inclined screen surface through the overflow weir. The surface gap of the screen is small (customizable 0.25-2 mm), which can accurately intercept fish skin fragments, scales and other solids, while the water flow is discharged smoothly from the gap of the screen plate. The gap on the back of the screen plate is large to avoid clogging. At the same time, the hydraulic effect pushes the intercepted material to the lower end for centralized discharge, and no additional energy consumption is required throughout the process.

2. Application scenarios of fish skin separation: efficient adaptation to enhance resource value

In the fish processing process, the separation of fish skin directly affects the efficiency of subsequent deep processing and product quality. The sieve bend screen has become the core equipment for fish skin processing with the following advantages:

- Efficient interception: The screen gap can be flexibly adjusted for fish skin fragments, grease and fine impurities to ensure separation accuracy.

- Continuous operation: The single machine can process 30 to 420 cubic meters of water per hour (depending on the model), meeting the high load requirements of large processing plants.

- Sanitary and environmentally friendly: Made of food-grade stainless steel 304, it is corrosion-resistant and easy to clean, meets the sanitation standards for aquatic product processing, and reduces the use of chemical detergents.

The sieve bend screen has become a benchmark equipment in the field of fish skin and water separation with its high efficiency, energy saving and environmental protection. Whether it is to improve processing efficiency or to help enterprises practice sustainable development, the hydraulic screen has demonstrated irreplaceable value.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060