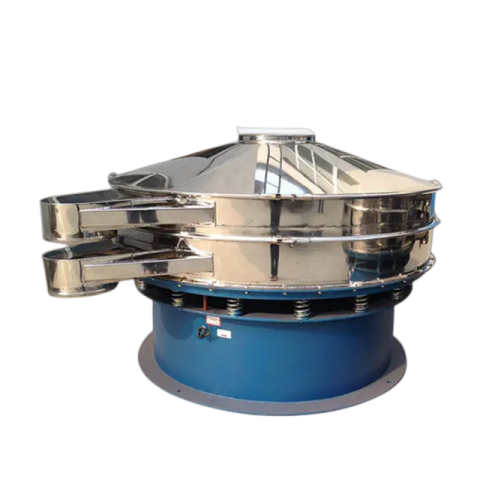

How does Vibrating Screen Working?

Vibrating screen is a precision equipment that combines mechanical dynamics and intelligent control. It is quietly promoting the quality upgrade of industries such as mining, chemical industry, and food.

1. Power core: precise cooperation of vibration motors.

The core power of the vibrating screen comes from the symmetrically installed vibration motor. When the internal eccentric block rotates at high speed, it generates regular centrifugal force, forming a three-dimensional composite force of horizontal, vertical, and inclined. This exciting force is not released in a disorderly manner, but forms a mechanical wave with a specific amplitude and frequency through precise calculation. When the two motors rotate synchronously in opposite directions at a specific angle, the exciting force is accurately superimposed on the motion trajectory of the screen box, and can be freely adjusted to a circular, elliptical or linear vibration mode to meet the motion characteristics of different materials.

2. Sorting art: the microscopic world of material movement

After starting, the vibrating screen builds a unique dynamic stage: the screen surface vibrates at a high frequency of 25 to 50 Hz, causing the material to produce a compound motion of "jumping-forward". Particles with a diameter of 0.5 mm complete a bounce cycle of thirty times per second on the screen surface. Larger particles slide along the screen surface due to insufficient kinetic energy, while fine particles penetrate the screen mesh by vibration waves. The gradient design of the multi-layer screen box allows the material to undergo multiple levels of "screening tests" during the falling process, and finally be accurately classified according to the particle size.

3. Intelligent purification: the technological transformation of modern vibrating screens.

Contemporary vibrating screens have evolved intelligent perception capabilities: built-in acceleration sensors monitor vibration parameters in real time.

From primary screening of mining crushing production lines to micron-level powder filtration in the pharmaceutical industry, the vibrating screen is vibrating three thousand times per minute to build a modern industrial fine sorting standard.

Any requirements, contact us now!

Nina

Email: nina@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 172 6957 1060