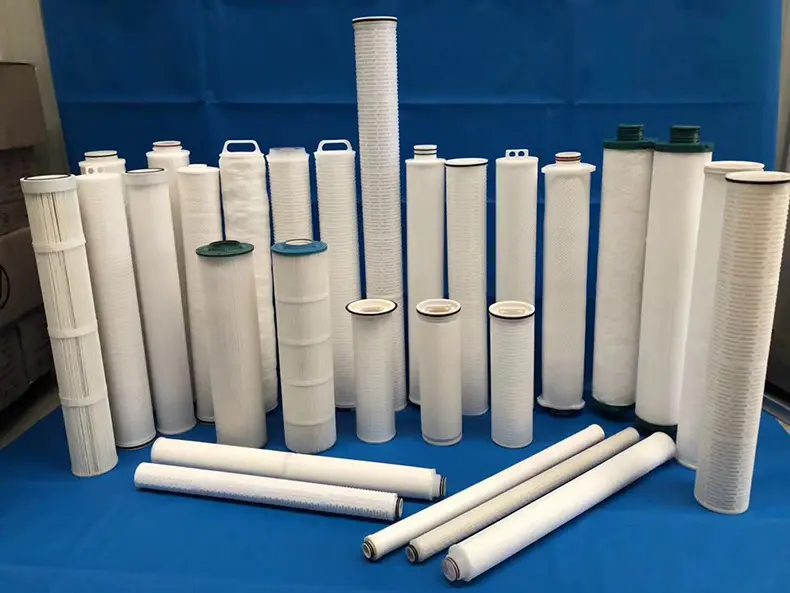

Common Filter Elements for Cartridge Filter

Cartridge filter is a new type of multi-functional filter, which consists of two parts: filter housing and filter element. The liquid to be filtered is pressed into the filter inlet, and pass through the filter element from the outside to the inside, and then discharged through the outlet. Impurities are trapped in the deep layer and surface of the filter element, so that the liquid can be filtered.

PP Meltblown Filter Element

The PP melt-blown filter element is made of polypropylene ultrafine fibers by thermal fusion entanglement. The fibers randomly form a three-dimensional microporous structure in space. The pore size of the pore size is distributed in a gradient along the flow direction of the filtrate. It integrates surface, deep and fine filtration and can be intercepted Impurities of different particle sizes.

The filter element precision range is 0.5-100μm, and its treatment capacity is more than 1.5 times that of the same precision filter element. Different types of end cap joints can be configured.

Wire Wound Filter Element

It is refined from textile fiber yarns with good filtration performance that are precisely wound on a porous skeleton. Its yarn materials include polypropylene fiber, acrylic fiber, absorbent cotton fiber, etc. By controlling the winding tightness and thinness of the yarn during winding, filter elements of different precision can be made.

It can effectively remove suspended solids, particles, etc. in the liquid. It can withstand high filtration pressure, and the filtration pore size is large on the outside and small on the inside. The material is made to meet the needs of various liquid filtration.

Pleated Mesh Filter Element

The pleated filter element is a precision filter device made of Polypropylene thermal spray fiber membrane, Nylon, PTFE microporous filter membrane, etc. as filter media, with small volume, large filter area and high precision. The filtration precision can range from 0.1μm to 60μm. The sealing of the filter element end cap and the connection of the overall structure are all hot-melt bonding. There are three types of filter element joints: 222 joints, 226 joints, and flat mouths.

Stainless steel pleated filter elements are widely used in environmental protection, petroleum, chemical, medical, high temperature gas filtration, scientific research, metallurgy, food, machinery and other industries.

Large Capacity Filter Element

The combination of surface filtration and deep filtration can greatly reduce the number of filter elements. The convenient handle design significantly reduces the time to replace the filter element, making the filter element replacement simple and portable.

The overall polypropylene design and hot-melt welding treatment can effectively prevent the end cap from falling off and secondary pollution. The folded design increases the filter area, so that the pressure drop is significantly lower than that of ordinary filter elements; the large-diameter design increases the treatment capacity to 1300L/min and prolongs the service life, reduce production costs. Equipped with a skeleton to enhance the pressure resistance of the filter element during use.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160