Beer Filtration Technology and Filtration Method

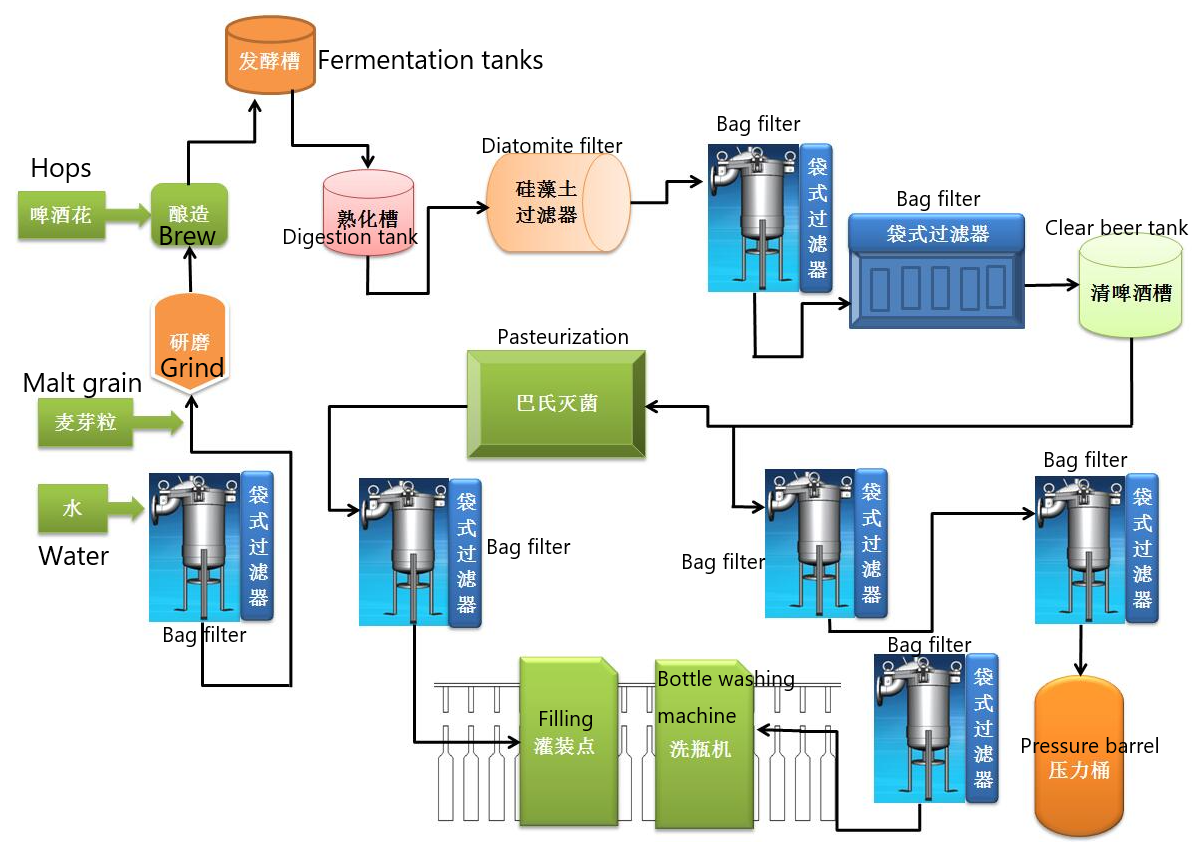

Filtration is required in the beer production process:

1. Process water filtration

The use of bag filters to treat the process water can remove particulate impurities and avoid water quality deterioration caused by seasonal changes or abnormal water pipelines, affecting the normal operation of production.

2. Deoxygenated water filtration

In recent years, low-alcohol beer has been favored by consumers, and beer dilution technology has been rapidly promoted. The dilution water should have the same quality characteristics as beer. Most breweries use post-filtration dilution technology (the production process of post-filtration dilution: post-cooked wine - beer filtration - wine mixing - into the sake tank), high-concentration dilution wine The mixer is installed after the fine filter. Since the beer will not be filtered after adding the dilution water, the quality requirements of the dilution water are very high. The dilution water prepared by the above filtration process is clear and transparent in appearance, without suspended matter and sediment, and is directly added to the wine, which is safe and reliable.

3. Filter before beer hardcover

In the actual production of domestic breweries, it is sometimes found that the diatomite filter will suddenly leak soil, resulting in the sudden blockage of the beer fine filter. In order to prevent this phenomenon and ensure the economy of production, it is recommended to install an economical and effective bag filter in front of the beer fine filter. The filter bag can effectively remove larger particles and some viscous impurities, and act as an alarm when the diatomite filter suddenly leaks. Although this will block the cheap filter bag, it protects the relatively expensive filter element.

4. Filter beer before canning

Experienced technicians know that even if the sake passes the inspection, sometimes after being transported to the packing house for filling, the beer in the bottle will still have black residue or other suspended matter. Installing a set of filters with a pore size of 1 micron in front of the filling machine can reduce the occurrence of this phenomenon.

5. Beer recycling and filtration

Due to various reasons, there will be a problem of half a bottle of wine or leaking wine after beer filling. The corresponding countermeasures vary from individual cases. Open bottle recycling is an economical and feasible method. A bag filter is installed after the pouring tank, which can retain impurities, bottle caps, and broken glass, effectively ensuring the deep filtration of the filter element behind.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160