What is Volute Dewatering Press?

Volute Dewatering Press mainly used in municipal sewage treatment projects and sludge water treatment systems in petrochemical, chemical, paper, pharmaceutical, leather and other industries.

Volute Dewatering Press, is a new type of environmental protection, energy-saving and efficient sludge treatment equipment.

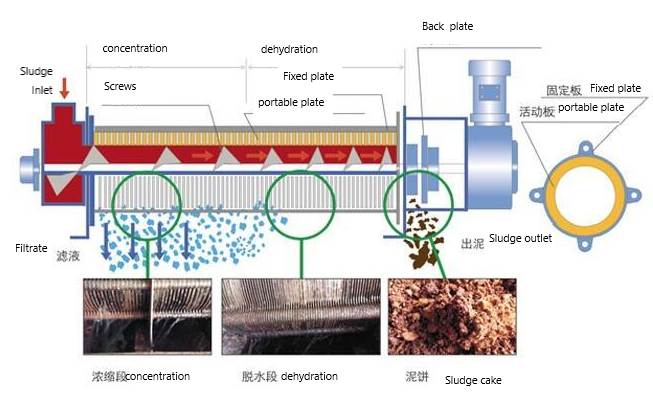

When the equipment is running, the sludge from the feed port into the filter cartridge by the spiral shaft spinner push and move to the discharge port, because the pitch between the spiral shaft spinner gradually narrows, so the pressure on the sludge is also increasing, and under the pressure difference for dewatering from the fixed plate and the portable plate filter gap. while the equipment relies on the self-cleaning function between the fixed plate and the portable plate, cleaning the filter gap to prevent clogging, sludge cake after full dehydration in the propellant of the spiral shaft from the discharge port.

- Small and compact design, dewatering machine contains an electronic control cabinet, metering tank, flocculation mixing tank and dewatering machine body. Small footprint and weight for easy maintenance and replacement.

- Suitable for dehydration of high and low concentrations of sludge. When low concentration (2000mg/L)sludge is dehydrated. There is no need to build a concentration pool, storage tank, reduce construction costs, reduce phosphorus release and anaerobic odor.

- Not easy to clog with self-cleaning function. No cleaning is required to prevent blockage of the filter, reduce flushing water consumption, reduce the burden of internal circulation. Good at dehydration of oily sludge.

- Simple operation, through the electronic control cabinet, and dosing device, sludge screw pump, drug pump, etc. to carry out a continuous 24 hours.

- Low-speed operation, spiral shaft speed of about 2-3 rpm, low power consumption. Fewer faults, low noise vibration, safe operation.

- Daily maintenance time is short and maintenance work is simple. The durable, almost all of the body is made of stainless steel to maximize service life. The replacement parts are only spiral shafts and portable plates.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160