Wedge Wire Screen Manufacturers - JX Filtration

Application: Mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries, screening liquids, powders and other materials, petroleum, chemical, metallurgy, mining, pharmaceutical purification, filtration tanks, water treatment equipment, drilling liquid purification.

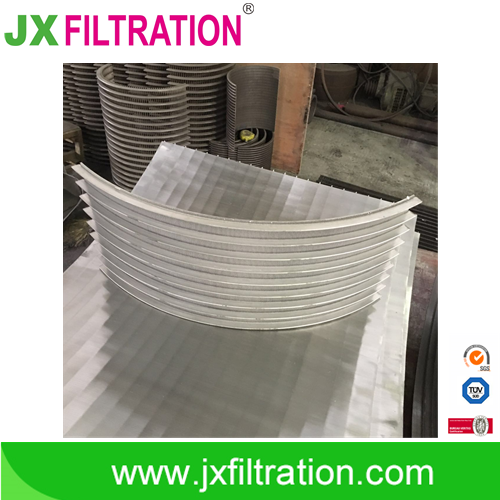

The Wedge Wire Screen is easy to permeate, wear and corrosion resistant. The section is trapezoidal and narrow on the top and wide on the bottom. Wedge wire screen has uniform slot size, stable welding quality and high opening rate, long service life, has the high strength, stiffness and load capacity. Wedge wire screen can make a variety of shapes of rigid screening filter device.

Features:

- Good abrasion resistance and long service life, more than ten times that of metal screens and 3-5 times that of ordinary rubber plate.

- The cost per ton of ore is lower than that of metal screens.

- Good moisture resistance and abrasion resistance.

- Shock absorption and noise reduction, more than 10bB times lower than metal screen.

- Automatic cleaning and high screening efficiency.

JX Filtration is specialized in designing and manufacturing various wedge wire screen products for decades, such as wedge wire panel, wedge wire sieve screen, wedge wire slot pipe and wedge wire strainer, etc.

The wedge profile wire and support can be customized. The construction material options include Low carbon steel, low carbon steel galvanizing, plastic spraying, stainless steel ( 304,316), duplex stainless steel 2205, etc. The minimum slot size we could make is 0.2mm.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160