China Rotating Drum Micro Strainer

Application: successfully applied to the treatment of surface water, especially to remove the plankton in the reservoir water.

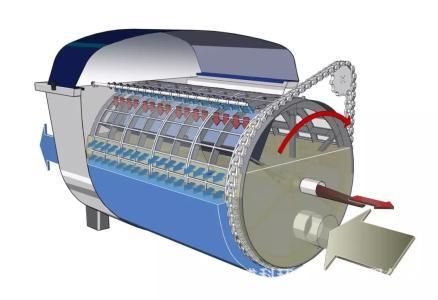

Internal structure and working principle

The rotating drum micro strainer can be placed in the water pool or working site, with 1/3 of its above the water surface. The water enters from the water tank through the inlet pipe (which also serves as the shaft of the drum strainer), and is filtered out of the drum screen, and the filtered water is led out along the tank.

There is a automatic backwashing device for the filter screen above the rotating drum micro strainer, and the drainage channel in the drum collects the washing water and drains it along the outlet pipe (as the support of the rotating drum strainer).

Technical specifications

The rotating drum micro strainer has three different drum screen type: wedge wire screen, perforated mesh screen, woven mesh screen. The wedge wire screen has the longest service life over 10 years.

The diameter of the drum is 0.3-3.0m, the length is equal to the diameter, and the treatment capacity is 250-36000 m3/d.

The specifications of stainless steel wedge wire mesh are 700 mesh/in2×100 mesh/in2, 500 meshes/in2×100 mesh/in2 and 400 mesh/in2×100 mesh/in2, which is approximately equivalent to the slot size of the filter screen 35~60μm.

The filtration strength can be 10-25L/(m2·s), and the amount of water used to clean the filter is 1% to 3% of the filtered water.

Any requirements, contact us now!

Grace

Email:grace@filtrationchina.com

Mobile/Whatsapp/WeChat:+86 17269571160